Editorial contributions

Air humidification for call centres

Air humidification technologies from the pioneer of hygienic air humidification

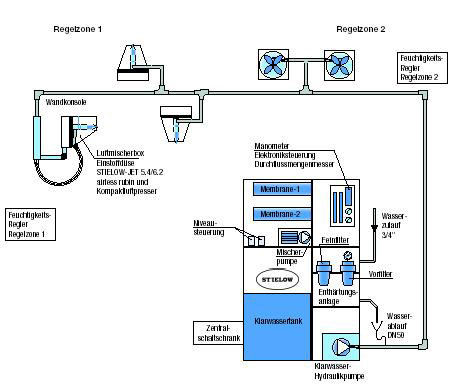

Direct room humidification is the keyword when it comes to replacing unhygienic and unhealthy air conditioning technology.

Sins of the past often led to technical concepts that were designed as air washers, tricklers or vaporisers in such a way that hygiene aspects were not taken into account. Only technical progress and clear guidelines such as DIN 6022 prompted some people to reconsider.

A manufacturer takes a different approach It is worth mentioning a manufacturer that has been taking a different approach for decades and has always prioritised the hygiene aspect. As early as the 1950s and 1960s, it designed hygienically perfect and exemplary systems - always using nozzle technology.

It is therefore only logical that the experience gained in this field since 1952 is also consistently utilised for new and demanding tasks in room air humidification. www.stielow.net

Direct room humidification is not only far more effective than conventional systems because the high humidification capacities are directly available in the room on site, it is also significantly cheaper to purchase and beats all known systems hands down when it comes to operating costs and maintenance. Professionally and technologically correctly implemented, they are technically fault-free or hygienically outstanding, like STIELOW air humidification technologies, which set standards here.

The manufacturer likes to talk about the creation of a "green lung", which has had a significant impact on ventilation and air conditioning in companies. The air is humidified "as finely as a breath of air" using state-of-the-art diamond nozzles supported by an air mixer box, so that the adiabatic cooling (evaporative cooling) is not noticeable and the system therefore does not have any adverse effects due to draughts or noise.

Air humidification in particular and its positive effects on performance and well-being in the workplace are completely underestimated by many companies.

In call centres and office buildings, the stress levels for employees are often unbearably high and therefore have a significant impact on their performance and ability to concentrate, which are of the utmost importance in such workplaces. Today, medical experts confirm that the right air humidification, even if it is artificial, is of great importance for health in the workplace.

Sick building syndrome has been known for a long time. It is now known that permanent irritation of the respiratory tract, fatigue and tiredness as well as headaches and itchy eyes are directly linked to the correct ventilation and humidity, especially in closed rooms, and that deficiency symptoms make people ill in the long term. leading occupational physicians therefore make corresponding recommendations for air humidification, always when these are hygienically perfect.

It's the nozzle that counts

Continuous operation of high-pressure nozzle systems places special demands on the

nozzle. Because the volume of water flowing through under high pressure leads to the nozzle being washed out, steel or

titanium nozzles can only have a limited service life, which must be taken into account because advanced wear on the nozzle is

not signalled and leads to sudden moisture precipitation or pools of water.

Operational impairments or costly damage are often the result. For this reason, particular attention must be paid to quality when selecting the nozzle. The Diamond nozzle from the manufacturer STIELOW is therefore particularly advantageous, as it has an extremely long service life and always delivers a perfect droplet spectrum.

This is where conventional steel and titanium nozzles are at a disadvantage because they tend to cause turbulence in the atomisation pattern even when slightly worn, which can quickly lead to a "heavy mist" and moisture precipitation.

Basically water treatment

The internal geometry of the fine nozzles requires demineralised and germ-free demineralised water. This task places special demands on a high-quality water treatment system.

Systems that produce appropriately osmotically treated water are clearly preferable here. Filtration is not recommended due to the high costs and handling effort involved.

If you have any questions about editorial contributions, please contact:

Stielow GmbH

Maschinen- und Apparatebau

60325 Frankfurt am Main

Telefon: 069 746178

E-Mail:

info@stielow.net

Satisfied employees are the goal

- Significant reduction in sick leave

- Improving the quality of work

- Elimination of static discharges (noticeable discharge shocks, e.g. due to synthetic fibre floors)

- Reducing the risk of computer crashes

- Air purification effect through reduction of suspended dust particles

- Creating a feel-good atmosphere in the workplace.

"California at home"

Dehumidifiers are important for classic car enthusiasts. This is because humidity reaches even the smallest cavity of a parked vehicle and gradually causes corrosion.

If the vehicle owner is lulled into a false sense of security, problems initially arise unnoticed which can lead to costly and massive damage.

Excessive humidity also damages solid wood and veneer fittings as well as leather upholstery and also affects the electrical system of any vehicle.

Car owners should therefore pay particular attention to the subject of air dehumidification.

Automobile museums and important classic car collections have been relying on dehumidifiers for decades, which ensure optimum conditions with low operating costs (from around 8 euros in electricity costs per month).

The purchase costs start at 497 euros - a purchase that saves costs in the long term.